Car manufacturers are responding to global semiconductor shortages by revamping their supply chain strategies and developing closer relationships with key suppliers.

German car giant BMW [BMW] last week announced that “to secure semiconductor supplies for the long-term” it had sealed a direct supply assurance agreement with microchip developer Inova Semiconductors and semiconductor maker GlobalFoundries [GFS].

According to BMW, the deal will secure the supply of “several million” microchips per year to be used in the smart LED technology deployed in its electric vehicle (EV) the iX.

“This partnership synchronises our capacity planning directly with semiconductor manufacturers and developers,” said Dr Andreas Wendt of BMW. “This improves planning reliability and transparency around the volumes needed.”

Robert Kraus, CEO of Inova, said the deal marked new territory: “This innovative approach will secure supplies for our end customers.”

“This partnership synchronises our capacity planning directly with semiconductor manufacturers and developers...This improves planning reliability and transparency around the volumes needed” - BMW's Andreas Wendt on the Inova and Global Foundries partnership

Other leaders making plans

Last week Stellantis [STLA], whose brands include Vauxhall and Chrysler, struck an agreement with Taiwanese electronics contract manufacturer Foxconn [2354.TW] to “design a family of purpose-built semiconductors”.

Stellantis hopes the partnership will meet over 80% of its semiconductor needs, helping to “modernise our components, reduce complexity and simplify the supply chain”.

US car giant Ford [F] has also announced a collaboration with GlobalFoundries which “opens the door for GF to create further semiconductor supply for Ford’s current vehicle lineup and joint research and development to address the growing demand for feature-rich chips”.

General Motors [GM] is also pursuing partnerships with Taiwan Semiconductor Manufacturing Company [TSM], NXP Semiconductors [NXPI], Qualcomm [QCOM] and others, reported the Financial Times.

Separately, German car firm Volkswagen [VWAGY] has sealed an agreement with lithium developer Vulcan Energy Resources [VUL.AX] to strengthen its battery technology know-how and secure “demand for future in-house cell production”.

Vulcan managing director Dr Francis Wedin said its lithium supply would be a “key enabler of VW’s target to produce carbon-neutral EVs”.

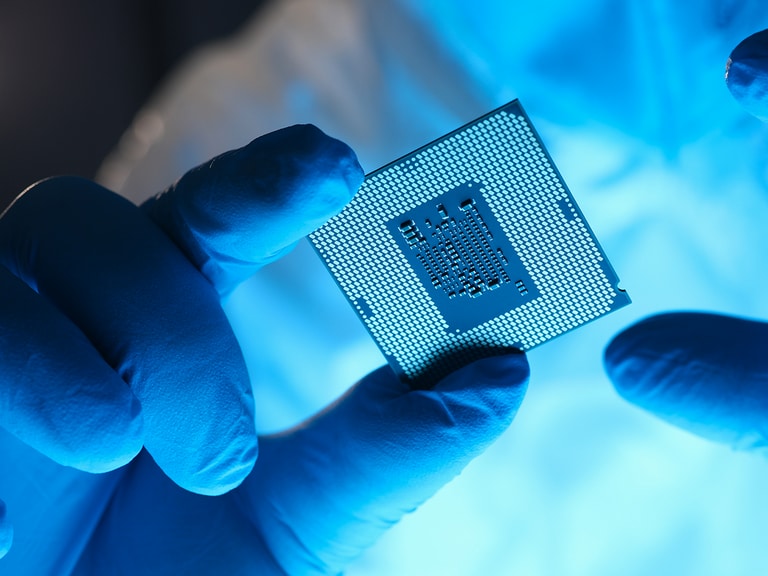

Crucial chips

The drive by manufacturers to transform from fossil fuel engines to EVs is a key reason car makers are so hungry for semiconductors and battery technology.

Semiconductors are also increasingly needed for advanced driver assistance and battery management systems, and automated connected devices.

Carmakers have blamed a shortage in supply – with demand also soaring from sectors such as 5G and consumer electronics during the pandemic – on faltering sales figures.

Stellantis recently revealed a 14% drop in third quarter revenues, compared with the same period last year battered by a 30% drop in planned production or 600,000 vehicles “due to unfulfilled semiconductor orders”.

Share prices have been more resilient with Stellantis up 7.2% in the 12 months to 16 December, Ford up 124%, BMW up 21.5% and General Motors up 38.9%.

Investors are feeling particularly bullish about carmakers’ plans for EVs and the policy tailwinds as governments ramp up the drive towards net-zero carbon emissions targets to reduce the pace of global warming.

124%

Ford's stock gain over 12 months to 16 December

2022: the chip squeeze continues

Still, predictions that the semiconductor supply crisis could continue have sharpened carmakers’ minds about the need to secure supply and keep their sales and EV innovations churning.

Glenn O’Donnell, vice-president and research director at advisory firm Forrester, told CNBC that the supply shortage could last until 2023. He sees data centres, PCs, cloud computing and cryptocurrency mining leading to “boom times ahead for chip demand”.

Nissan [NSANY] boss Makoto Uchida recently told the BBC that it was too early to say when normal deliveries would resume. “The new variant [Omicron] could add pressure to that, so how well we react is going to be crucial,” he said.

However, JPMorgan’s co-head of Asia-Pacific technology, media and telecom research, Gokul Hariharan, doesn’t expect a shortage in 2023. Instead Hariharan sees the supply squeeze improving in the second half of next year. “There is capacity coming online,” he said.

Carmakers are getting ahead of the curve. They can’t control everything, as new COVID-19 outbreaks could once again close factories and disrupt supply chains, but they are giving themselves the best chance of steering a smoother path to success in the years ahead.

Continue reading for FREE

- Includes free newsletter updates, unsubscribe anytime. Privacy policy